Quality Assurance in PFAS Site Investigations – Part 1: Source Water Sampling

Our PFAS team at LimnoTech has investigated dozens of sites for legacy PFAS contamination, mainly at commercial airports and chrome plating facilities. This article is the first in a series of “lessons learned” about the value of collecting different kinds of quality assurance samples during PFAS investigations.

By Scott Bell, Senior Environmental Engineer & Vice President and Christopher Behnke, Field Services Manager & Environmental Geologist (Ann Arbor, MI)

April 18, 2024

PFAS Site Investigations and Lessons Learned

Since 2017, our PFAS team at LimnoTech has investigated dozens of sites for legacy PFAS contamination, mainly at commercial airports and chrome plating facilities. During that time, we’ve seen new regulatory criteria come into play, reflecting increasingly lower numeric standards, sometimes with values as low as single-digit parts per trillion. At the same time, we’ve watched the list of PFAS compounds of concern grow. Our clients have asked us to develop conceptual site models that explain PFAS fate and transport at these sites, as well as to differentiate PFAS from different sources. As with most of our work, the cornerstone of success has been to start with high-quality data.

This article is the first in a series of “lessons learned” about the value of collecting different kinds of quality assurance samples during PFAS investigations. Our series starts with this discussion of “source water” samples – what they are, why we collect them, and what our data show. Future articles will discuss other data quality topics such as equipment blanks, field blanks, duplicate samples, and environmental influences during sampling, including rainfall.

Source Water for PFAS Sampling

So, what do we mean by “source water” as it relates to PFAS sampling? Basically, what we’re referring to is water used during site investigations for drilling and equipment decontamination. These investigation-related activities sometimes require a lot of “clean” water, meaning water that is free from the chemicals we’re trying to measure in the environment. Obviously, if PFAS is present in the water used for these activities, it poses the risk of introducing contamination to the environmental media being sampled. Given the very low detection limits that are measured, even low concentrations of PFAS might lead to false positive detections in the media, particularly in aqueous samples.

These investigation-related activities sometimes require a lot of “clean” water, meaning water that is free from the chemicals we’re trying to measure in the environment.

Typically, this water comes from one of two sources. First, and likely most commonly, it is taken from the water supply to the facility being investigated, sourced from taps, spigots, or hydrants that are accessible to the investigation team. However, it’s not uncommon for drilling contractors to (at least initially) fill their water tanks off-site at their own facility, as the increased weight apparently allows for smoother driving conditions for the drill rig. Once the rig is onsite, it typically doesn’t leave until the work is completed. At this point, it should also be noted that when drilling water is used during drilling, there are two potential sources of sample contamination. The water itself may contain PFAS at the off-site source, and the driller’s water tank may have been unknowingly contaminated with PFAS during previous uses at other sites. Residual PFAS on the tank material itself may leach into otherwise PFAS-free water and contaminate samples.

Source water used during site investigations for drilling and equipment decontamination may come from the water supply to the facility being investigated, sourced from taps, spigots, or hydrants that are accessible to the investigation team.

Precautions Taken to Avoid and Identify PFAS Sample Contamination

To address these concerns, we take the obvious precautions. If the onsite water supply is a municipal supply that has been tested for PFAS, we look at those results to determine whether PFAS was detected, and if so, we seek an alternate water source. If the water supply at the site is from an onsite well, we evaluate proximity and direction to known PFAS sources and avoid using that water if it’s near to or downgradient from a potential PFAS source. In all cases, however, it’s become our standard practice to collect a sample of the water used for drilling and/or decontamination. While the data from these samples won’t prevent a potential sample contamination problem, they can help identify one and avoid drawing misleading conclusions from our investigation results.

At $300 or more per sample (closer to $400 when Method 1633 is promulgated), it’s reasonable to ask whether the extra effort and expense of collecting source water samples is worth it. To answer that, we compiled data from 16 of our sites, representing 46 unique source water samples. This means that multiple samples came from each site, which is not unusual, especially in the case of airports.

“…it’s become our standard practice to collect a sample of the water used for drilling and/or decontamination. While the data from these samples won’t prevent a potential sample contamination problem, they can help identify one and avoid drawing misleading conclusions from our investigation results.”

Airports are large, and PFAS investigations may include areas that are widely separated, meaning that field crew may be accessing the water supply at different locations to support their investigation. Although the water at two separate spigots or hydrants may originate from the same source, we still prefer to collect source water samples from each location where the water is accessed. Sometimes, investigations can extend over years and include multiple phases. In those cases, we like to collect source water samples from each phase, just in case the water supply quality changes over time.

Detection of PFAS in Source Water Samples

So, what have we observed in the source water samples from our site investigations? Here’s a summary of our findings and observations:

- Our data set showed that it is more likely than not to detect PFAS in water used for drilling and equipment decontamination. Fourteen of the 16 sites evaluated for this paper had at least one source water sample with measurable PFAS. And of the 46 samples included, more than half (25 or 54.5%) had measurable PFAS.

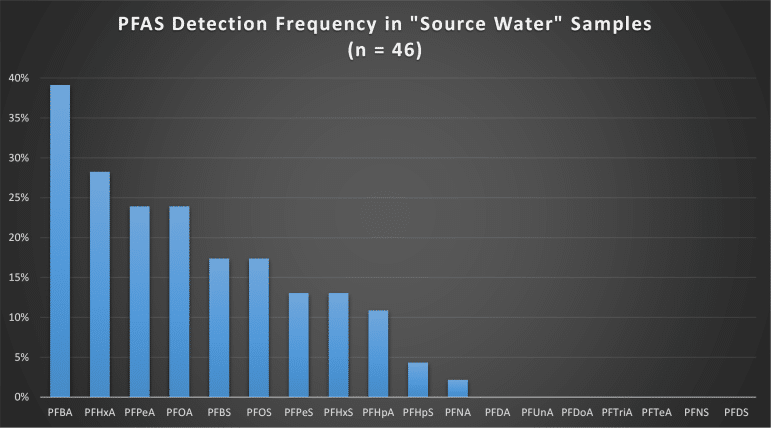

- Perfluorobutanoic acid (PFBA) was the most commonly detected PFAS, with measurable concentrations found in 39% of the samples. This was followed by perfluorohexanoic acid (PFHxA) detected in 28% of the samples, then perfluoropentanoic acid (PFPeA) and perfluorooctanoic acid (PFOA), each detected in 24% of our samples. That latter finding is very significant, as PFOA is one of the most regulated PFAS, and we found it in nearly a quarter of the samples from the water we used for drilling and/or equipment decontamination.

- Perfluorooctane sulfonic acid (PFOS), which is the other most regulated PFAS, was measured in 17% of the samples. The graph below shows the detection rates for the most commonly measured C4 – C14 carboxylates and C4 – C10 sulfonates.

- Measured concentrations in these samples were, for the most part, between 1 and 6 ng/L. While single-digit ng/L concentration may not seem like much, it’s worth pointing out that states are moving towards, or have already promulgated, single-digit cleanup criteria. And the EPA has proposed maximum contaminant levels (MCLs) for PFOS and PFOA in drinking water of 4 ng/L each.

- One notable outlier was the detection of PFOS at 14.7 ng/L in a sample collected from a hose inside a service building at an airport. This detection is noteworthy because the sample was collected from the end of a hose, and water supply samples collected from other locations at the same airport were all non-detect for PFOS. This led us to conclude that the detected PFOS was likely introduced from the hose itself.

This graph shows the detection rates for the most commonly measured C4 – C14 carboxylates and C4 – C10 sulfonates.

Even though the concentrations we’ve detected in our “source water” samples have been low, they’ve played an important role in our data interpretation, along with the other quality assurance samples we routinely collect. For example, in some cases, the presence of detectable compounds in source water, even at low levels, can help explain very low-level detections in the media being sampled and help argue against trying to delineate to “non-detect” levels in the media.

Source Water Sample Recommendations for PFAS Site Investigations

We plan to continue collecting what we refer to as “source water samples,” samples of the water we use for drilling and equipment decontamination at our PFAS investigation sites, and we offer the following recommendations for all PFAS site investigations:

- Collect samples of each water source used for drilling or equipment decontamination.

- If drilling contractors are supplying their own water from an off-site source, collect a sample and ask them to identify the source. Also, ask them where they’ve recently used the water tank they’re using on your site.

- If an onsite water supply is being used, understand the source of that water. If it’s a municipal water supply, determine whether any PFAS testing has been done and obtain the results.

- If the water supply is from onsite wells, determine the location and depth of the wells and evaluate the potential for those wells to be impacted by the PFAS being investigated based on proximity and groundwater flow direction. If it’s too early in the investigation to make these determinations, sample the water supply and examine the results before using the water in the investigation.

- Wherever possible, collect water samples directly from taps, spigots, or hydrants and avoid sampling from hoses.

Hopefully, you found this article informative and helpful in considering and building quality assurance protocols for source water used in PFAS sampling during PFAS site investigations. In the coming months, look for subsequent articles on other types of quality assurance samples that are useful in PFAS investigations.

If you have any questions about PFAS analysis methods, regulations, or site investigations or would like to discuss your PFAS-related needs, contact Scott Bell at sbell@limno.com.

This article is the twelfth in a series of articles authored by LimnoTech staff on PFAS-related issues. Follow us on LinkedIn and check the Insights & Perspectives page on our website for more information and updates. Links to the other PFAS articles in this series are provided below:

PFAS – Emerging, But Not New

Sampling for PFAS Requires Caution

PFAS Analysis – The New Wild West

Aviation and PFAS – What’s the Connection?

PFAS – The Next Wastewater Utility Challenge?

Should Municipalities Worry About PFAS?

PFAS – How Low Can You Go?

Key Considerations for PFAS Field Investigations

What Would A PFOS And PFOA Hazardous Substance Designation Under CERCLA Mean For The Business Sector?

PFAS – How Low Can You Go? Now We Know!

Method 1633 For PFAS In Aqueous Samples

Scott Bell, PE, is the Vice President of Business Operations and a Senior Environmental Engineer at LimnoTech. Scott has been with LimnoTech since 1992. He manages projects for various industrial, municipal, and federal clients. Scott has technical expertise in environmental remediation and restoration and is LimnoTech’s practice leader for PFAS and emerging contaminants. In that role, he has overseen and directed PFAS-related investigations at two dozen airports and industrial sites. Throughout his career at LimnoTech, Scott has planned and executed scores of hydrologic and hydraulic engineering, water quality management, wastewater discharge impact analysis, stormwater management, and engineering feasibility evaluation projects across North America. He has taught professional development courses for the Engineering Society of Detroit, delivered numerous technical papers and presentations, and served on several professional boards and committees.

Christopher Behnke serves as the Field Services Manager at LimnoTech. Chris has 23 years of experience as a Geologist conducting environmental sampling of various types, including surface water, groundwater, soil, sediment, and air. Each collection method requires consideration for a distinct, site-specific approach to collect the most representative sample possible based on existing conditions. Chris has experience with GIS, Excel, and various instrument-related programs used for field data collection. These skills are utilized in the planning, implementing, and reporting numerous data collection efforts. Chris’ experience included the collection of soil, groundwater, and stormwater runoff samples around airfields to characterize PFAS impacts from past use of AFFF and provide oversight for field investigations of PFAS. He has conducted fieldwork at several airports to monitor the environmental impacts of aircraft deicing and has also conducted investigations of PFAS and other contaminants at numerous industrial sites.