Quality Assurance in PFAS Site Investigations – Part 2: Equipment Blanks

Equipment blanks: What are they, why do we collect them, and what does our data from dozens of site investigations show?

By Scott Bell, Senior Environmental Engineer & Vice President, Christopher Behnke, Field Services Manager & Environmental Geologist, and Jessica Bleha, Hydrogeologist, PG (Ann Arbor, MI)

June 21, 2024

PFAS Site Investigations and Lessons Learned

This article is the second in our series on the value of quality assurance samples during PFAS investigations and lessons learned (see Part 1: Source Water Sampling). The subject of this article is equipment blanks: what they are, why we collect them, and what our data from dozens of site investigations show. Future articles will discuss other data quality topics such as field blanks, duplicate samples, and environmental influences during sampling, including rainfall.

What are Equipment Blanks, and Why Do We Collect Them?

Equipment blanks, sometimes called “rinsate blanks,” are samples of analyte-free water exposed to sampling equipment to determine the potential for contamination from the sampling equipment. Historically, the main purpose of collecting equipment blanks was to assess the potential for sample contamination due to inadequate equipment decontamination procedures. In other words, “to demonstrate that sample collection and processing equipment and equipment-cleaning procedures are not sources of contamination (1).

With the emergence of PFAS as a contaminant of concern, there has also been concern over the potential for sampling materials themselves, right “off-the-shelf,” to contaminate samples with PFAS. Sampling guidance highlights this issue with statements like “Contact with sampling supplies or equipment is the most likely pathway for potential cross-contamination (2).” Although recent research (3) has shown that the potential for sample contamination from sampling materials is likely more limited than originally thought when PFAS first emerged as a concern, caution is still advised. In our experience, there’s no question that the collection of equipment blanks can help identify when sample contamination from sampling equipment has potentially occurred during an investigation.

Equipment Blank Collection Procedures

In our investigations, we follow the general equipment blank approach recommended in the Michigan EGLE guidance (2), which states, “The equipment blank should be collected by passing laboratory-verified PFAS-free water over or through decontaminated field sampling equipment before collecting samples to assess the adequacy of the decontamination process and/or to evaluate potential contamination from the equipment used during sampling.” PFAS-free water is readily available from the labs we use for PFAS analysis. Sometimes, it’s provided for free, and sometimes, the labs charge for it, but it’s available and normally delivered with lab-provided sample containers.

That said, PFAS-free water is not typically supplied in quantities that allow for its use during the entire decontamination process. This underlines the importance of quantifying any potential PFAS concentration in source water, as covered in Part 1 of this series. When an equipment blank is warranted but cannot be collected using PFAS-free water, such as through a power washer or a rig-mounted water injection pump, a pre-and post-equipment contact comparison using source water may be all that’s feasible. This method might be employed to check for impacts from a hose used to fill an onboard water tank or internal drill rig hoses.

For reusable sampling equipment, such as a bucket auger used for soil sampling, we collect an equipment blank by pouring a quantity of PFAS-free water over the part of the equipment that comes in direct contact with the sample media after equipment decontamination and collect it in the appropriate sample containers. For disposable sampling materials, like the silicone or HDPE (high-density polyethylene) tubing used with groundwater sampling pumps, we pump PFAS-free water through a length of unused tubing and collect it in the appropriate sample containers.

For reusable sampling equipment, an equipment blank is collected by pouring a quantity of PFAS-free water over the part of the equipment that comes in direct contact with the sample media after equipment decontamination.

The equipment blanks are handled, stored, and shipped along with the rest of the samples from the investigation. The number of equipment blanks is specified in the investigation work plan or the quality assurance project plan (QAPP). The actual number of equipment blanks may vary depending on the scope and nature of the investigation and the number and variety of materials being used.

Observations on Our Equipment Blank Data

For this article, we assembled data from 136 equipment blanks collected from 16 PFAS investigation sites between 2018 and 2023. General observations on the data are presented below.

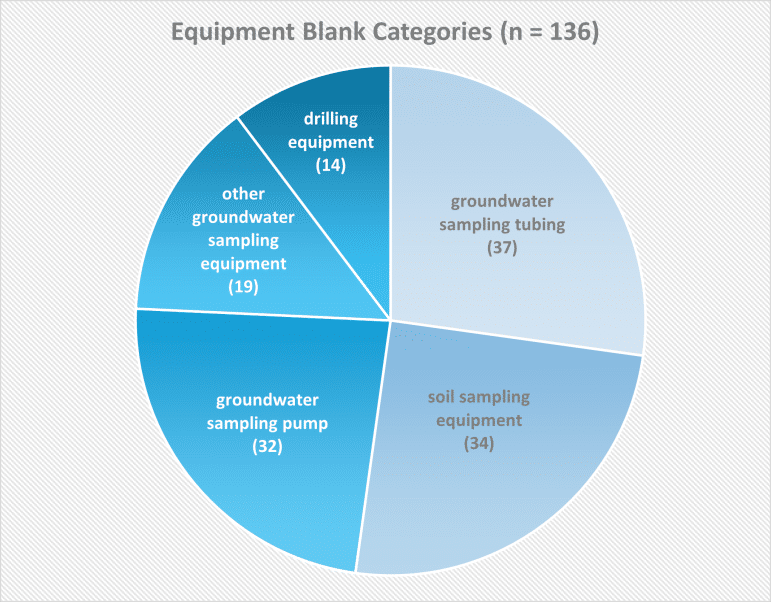

The equipment blank data reviewed here represents a variety of sampling equipment and materials that we grouped into five categories:

- Soil sampling equipment, such as bucket augers, split-spoon samplers, and push-probe core barrels.

- Groundwater sampling tubing used with either submersible or peristaltic pumps.

- Groundwater sampling pumps, particularly submersible pumps that come in direct contact with groundwater being sampled.

- Other groundwater sampling equipment, such as temporary well points, push-ahead samplers, Henry samplers (used for pore water sampling), and water level meters (used for measuring depth-to-water in wells).

- Drilling equipment, including cutting shoes, plastic liners, and drill rods.

The distribution of the 136 equipment blanks among these five categories is presented in Figure 1.

Figure 1. LimnoTech collected equipment blanks from a variety of sampling equipment and materials from 16 PFAS investigation sites between 2018 and 2023.

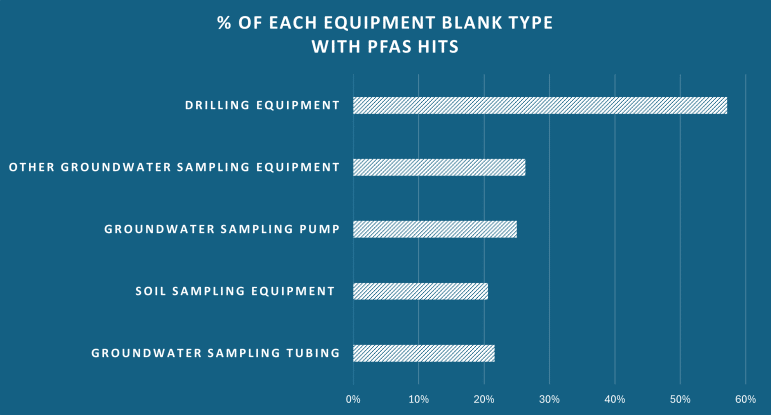

The first question we wanted to answer was, did we have any positive PFAS detections in our equipment blank data and if so, did they occur more commonly in one type of equipment over another? In an ideal world, equipment decontamination would be complete and wouldn’t yield any detectable PFAS. Likewise, if we choose our sampling materials properly, we should be able to avoid materials that might leach PFAS. Unfortunately, we did get several measurable detections in our equipment blanks. Of the 136 equipment blanks reviewed, at least one PFAS was detected in 38 (28%) of them. Figure 2 shows the percentage of equipment blanks in each category that had positive detections.

Figure 2. Percentage of equipment blanks in each category with positive detections, where drilling equipment had the highest percentage of positive PFAS detections (57%).

It’s not a surprise that the category with the highest percentage of positive detections (57%) was drilling equipment. The reason for this is that drilling equipment is simply more challenging to thoroughly decontaminate. Of the other equipment categories, it’s worth noting that most positive detections (70%) occurred in the earliest samples when we were first ramping up with PFAS site investigations (2018-2020). The number of equipment blank detections decreased significantly between 2021-2023, reflecting more attention being paid to decontamination procedures and clean sampling methods.

A review of the data from the equipment blanks with positive PFAS detections yields some interesting observations, including the following.

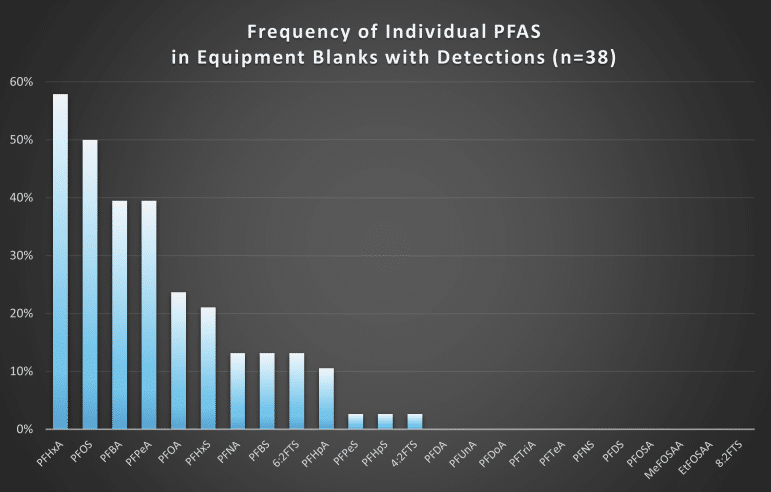

- The most commonly detected PFAS in equipment blanks was perfluorohexanoic acid (PFHxA), measured in 58% of the equipment blanks with detections. This is somewhat unexpected because, although PFHxA is certainly present at many of the sites investigated, it is not the most prevalent PFAS.

- The second most commonly measured PFAS was perfluorooctane sulfonic acid (PFOS), which is not surprising as it is one of the most commonly detected PFAS at our investigation sites and is often measured at very high concentrations. Figure 3 shows the detection frequency of individual PFAS.

- Perfluoroalkyl carboxylic acids (PFCAs) were more commonly detected in our equipment blanks than perfluoroalkyl sulfonic acids (PFSAs).

- With one exception, PFAS were only detected at single-digit parts per trillion (ppt) concentrations in the equipment blanks. The sole exception was an equipment blank collected from soil sampling equipment during one of our earliest investigations in 2019, which indicated that we needed to implement more rigorous decontamination procedures.

- We did not observe a significant difference in the frequency of PFAS detections between soil sampling equipment blanks and groundwater sampling equipment blanks.

Figure 3. Detection frequency of individual PFAS in equipment blanks. The most commonly detected PFAS were PFHxA and PFOS.

Recommendations for Use of Equipment Blanks in PFAS Site Investigations

Equipment blanks are essential for data quality assurance in PFAS investigations. Here are a few recommendations for collecting them based on our experience:

- At a minimum, at least one equipment blank should be collected for each piece of sampling equipment being used during a PFAS investigation.

- If a particular piece of sampling equipment is being used on consecutive days, such as a submersible groundwater sampling pump, consider collecting one equipment blank from it on each day of use.

- At least one equipment blank should be collected from each batch of silicone or HDPE tubing used during an investigation.

- Whenever feasible, PFAS-free water from a certified lab should be used when collecting equipment blanks.

We hope you found this article informative and helpful in considering and building quality assurance protocols for the collection of equipment blanks during PFAS site investigations. We’re planning future articles on other types of quality assurance samples that are useful in PFAS investigation.

If you have any questions about PFAS analysis methods, regulations, or site investigations or would like to discuss your PFAS-related needs, contact Scott Bell at sbell@limno.com.

Citations:

(1) Mueller, D.K., T.L. Schertz, J.D. Martin and M.W. Sandstrom. 2015. “Design, analysis, and interpretation of field quality-control data for water-sampling projects: Techniques and Methods 4-C4.” U.S. Geological Survey Techniques and Methods, Book 4, Chapter C4, 54 p. DOI: 10.3133/tm4C4.

(2) Michigan Department of Environment, Great Lakes, and Energy (EGLE). “General PFAS Sampling Guidance.” January 2024.

(3) Field, J. et al. 2021. “Assessing the Potential for Bias in PFAS Concentrations during Groundwater and Surface Water Sampling.” Prepared for the Department of Defense Strategic Environmental Research and Development Program (SERDP). SERDP Project ER19-1205.

This article is the thirteenth in a series of articles authored by LimnoTech staff on PFAS-related issues. Follow us on LinkedIn and check the Insights & Perspectives page on our website for more information and updates. Links to the other PFAS articles in this series are provided below:

PFAS – Emerging, But Not New

Sampling for PFAS Requires Caution

PFAS Analysis – The New Wild West

Aviation and PFAS – What’s the Connection?

PFAS – The Next Wastewater Utility Challenge?

Should Municipalities Worry About PFAS?

PFAS – How Low Can You Go?

Key Considerations for PFAS Field Investigations

What Would A PFOS And PFOA Hazardous Substance Designation Under CERCLA Mean For The Business Sector?

PFAS – How Low Can You Go? Now We Know!

Method 1633 For PFAS In Aqueous Samples

Quality Assurance in PFAS Site Investigations – Part 1: Source Water Sampling

Scott Bell, PE, is the Vice President of Business Operations and a Senior Environmental Engineer at LimnoTech. Scott has been with LimnoTech since 1992. He manages projects for various industrial, municipal, and federal clients. Scott has technical expertise in environmental remediation and restoration and is LimnoTech’s practice leader for PFAS and emerging contaminants. In that role, he has overseen and directed PFAS-related investigations at two dozen airports and industrial sites. Throughout his career at LimnoTech, Scott has planned and executed scores of hydrologic and hydraulic engineering, water quality management, wastewater discharge impact analysis, stormwater management, and engineering feasibility evaluation projects across North America. He has taught professional development courses for the Engineering Society of Detroit, delivered numerous technical papers and presentations, and served on several professional boards and committees.

Christopher Behnke serves as the Field Services Manager at LimnoTech. Chris has 23 years of experience as a Geologist conducting environmental sampling of various types, including surface water, groundwater, soil, sediment, and air. Each collection method requires consideration for a distinct, site-specific approach to collect the most representative sample possible based on existing conditions. Chris has experience with GIS, Excel, and various instrument-related programs used for field data collection. These skills are utilized in the planning, implementing, and reporting numerous data collection efforts. Chris’ experience included the collection of soil, groundwater, and stormwater runoff samples around airfields to characterize PFAS impacts from past use of AFFF and provide oversight for field investigations of PFAS. He has conducted fieldwork at several airports to monitor the environmental impacts of aircraft deicing and has also conducted investigations of PFAS and other contaminants at numerous industrial sites.

Jessica Bleha, PG, is a Hydrogeologist with more than 15 years of environmental consulting experience and over a decade of work in project management, planning, and coordination. Jessica’s expertise includes hydrogeological assessments of surface and groundwater resources, environmental site assessments, conceptual modeling, data management systems, mine remediation and permitting, monitoring wells, soil boring, and remediation system installations. She has supported investigations of PFAS impacts in groundwater, soil, and stormwater from past use of aqueous film-forming foam (AFFF) at 11 airports in Michigan. Her work includes oversight of drilling subcontractors, installation of groundwater wells, and sample collection. Jessica has performed and overseen soil, groundwater, and surface water investigations for PFAS and other contaminants, evaluated municipal well-pumping test data, and provided remedial design and support for a Superfund site. She is proficient in various environmental and engineering software (ArcGIS, AQTESOLV, LogPlot, RockWorks20).